What Is Load Planning Software?

Load planning software refers to computer programs that carry out functions related to packing cargo. Typically, load planning software will quickly determine the optimal way to stack freight within given dimensions.

Container packing software also factors in things like axle weight requirements, trucking regulations, and loading strategies. By minimizing the potential for human error and streamlining load planning services, Syntelic’s Load Planning software accounts for multiple factors.

How Does Syntelic’s Load Planning Software Work?

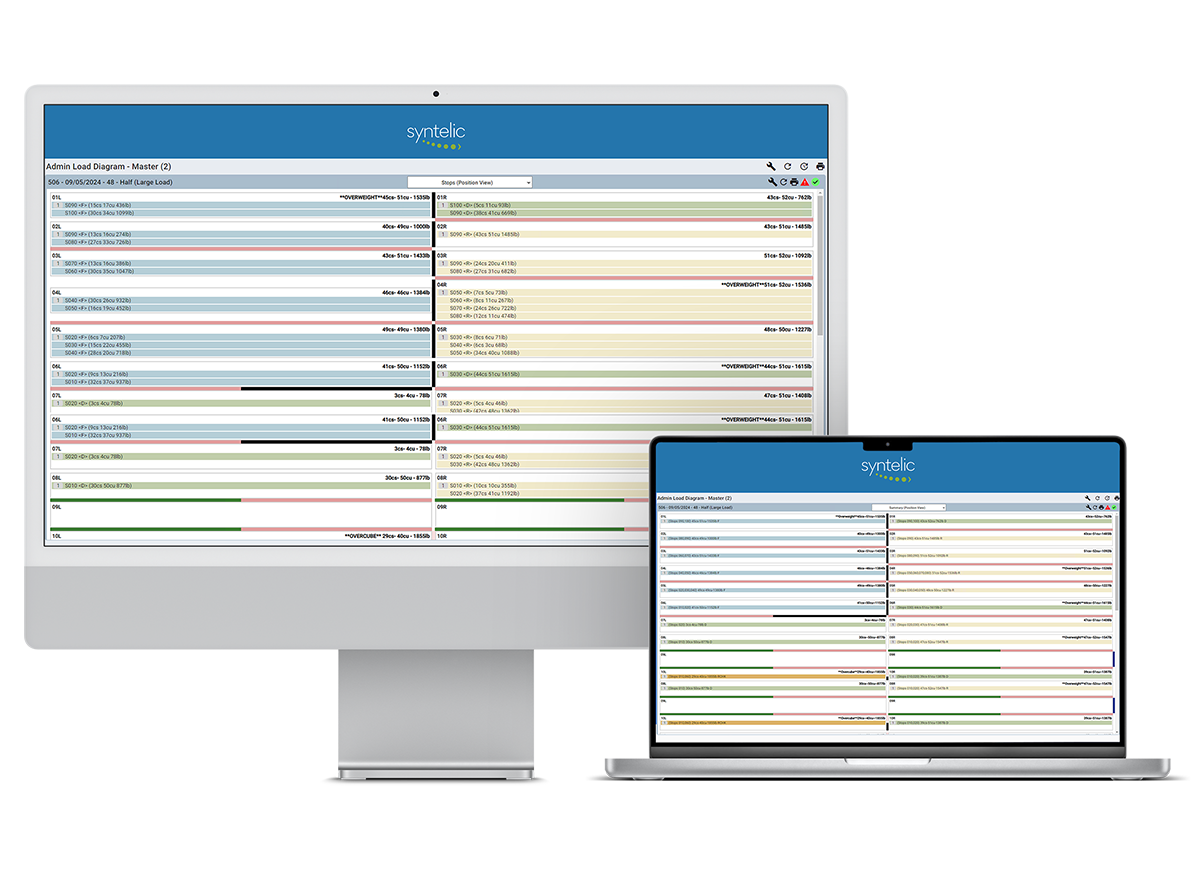

Syntelic load optimization software determines where each and every case should be placed on an outbound load. Every load is examined uniquely, based on its own particular order volume and product mix characteristics.

Load Planning uses Syntelic’s advanced optimization techniques to search through thousands of options to select the best configuration based on your business rules without the use of fixed templates. The result is a custom vehicle configuration constructed dynamically for each load.

Load Planning Software Benefits

Simple User Interface

Save Load Planning Time

Save Loading Time

Lower Selection Time

Streamline Unloading Process

Save Driver Time

Better Customer Service

Reduce OS&D Issues

Avoid Breaking Regulations

Improve Tractor Trailer Utilization

Integrations With Other Tools

Load planning software is an essential tool in today’s world, but it is not the only trucking software that can help improve your business. Other programs can help with route planning and transportation analytics to provide a comprehensive upgrade to your system.

These applications can couple with the load planner to drastically improve productivity and customer satisfaction. They will help you get what you need to where you need in the best way possible.

How Does Syntelic’s Load Planning Software Compare With Competitors?

Here at Syntelic, we pride ourselves on understanding our clients. We’re not just here to sell a product, we’re here to improve the trucking industry. Our deep knowledge of what it takes to run a solid delivery company helps us cater to your specific needs.

Use Our Load Planning Services to Optimize Your Truck Loading Process

If you are looking to grow your business, improve your delivery service, and optimize your loading process, Syntelic’s software is exactly what you need. We offer customizable plans that will integrate straight into your existing load system.

Reach out to our team if you’re interested in our services or simply have more questions about how we work.

Load Planning Software FAQ

What is load optimization?

Load optimization is the process of consolidating and arranging cargo to a container’s full capacity. Finding the most efficient load sequence will save the loader time and effort that can be put towards other tasks.

Load optimization has become a necessary part of running a delivery company. To keep up with growing delivery demands, you must maximize every opportunity to create a more efficient process.

What does a load planner do?

A load planner uses an algorithm to determine the best possible loading method for filling up your tractor trailer. It will show you how much can fit, how the cargo should be loaded, and how to distribute the weight.

Should I use software to perform load planning?

Even for situations that require complex loading patterns, a load planning software can greatly increase the efficiency of your business. Our software does not cut corners, it performs the same function as a person would in a fraction of the time. It factors in trucking regulations, weight restrictions, and many more metrics that a human could miss after repetitive tasks.

The attention to detail and speed of our program make it a great option no matter what loads you need to optimize.

What is the load optimization algorithm?

Our software searches through a variety of different options to find which is best suited to your specific situation. Instead of using fixed templates, the software will design a custom plan for each individual load—taking into account the size of the vehicle, the weight it can hold, and the dimensions of the cargo.

How do I implement Syntelic load planning software?

When you choose to move forward with our product, our team will help you integrate the application with your existing system. Our staff will show you how you can use Syntelic’s software to your benefit. Once we feel that you are comfortable with the program, we will turn it over to you and remain ready to provide further assistance if needed.

What is the difference between FCL/FTL and LCL/LTL shipping?

Full container load (FCL) and full truckload (FTL) shipments are packed directly by the shipper for the carrier. This happens when a shipper can fully fill the tractor trailer and it doesn’t need additional rearranging before continuing in the process.

Less-than-truckload (LTL) and less-than-container load (LCL) shipments occur when the cargo must be packed multiple times with different items before it’s shipped. Many times this requires the help of a 3PL or consolidation company. There may be multiple stages throughout the shipment when cargo will be palletized, removed, rearranged, or added.

Need Help with Your Product or Service?

We're here to help.

Contact Us Today

Schedule a Meeting

Interested in talking to someone at Syntelic? Schedule a meeting.

Customer Support

240-686-1180 ext. 2

support@syntelic.com