Resources

Measurements for Vehicle Axle Weight Estimates

Many distribution organizations face the challenge of loading their trucks is a manner that balances the weight across axles in order to achieve safe configurations and to comply with national, state and local regulations. Due to the variety of products and the placement options for those products within the truck, determining the actual weight that will be allocated to each axle can be difficult.

Syntelic’s Load Planning product has the ability to provide reliable estimates of axle weights. Load Planning determines which products will be assigned to each pallet position. These assignments are dynamically adjusted by the planning algorithm in a manner that distributes the weight (within other constraints assigned to the load) in proportion to the capacity of each axle.

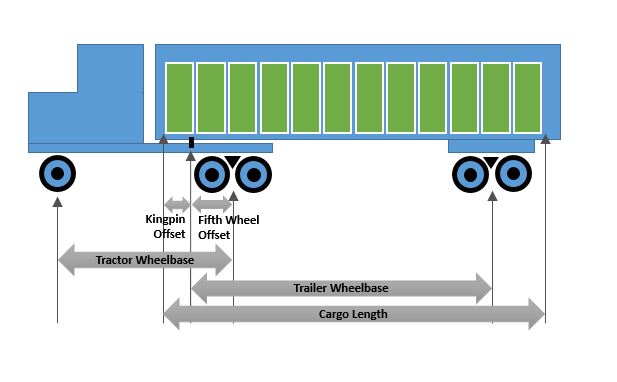

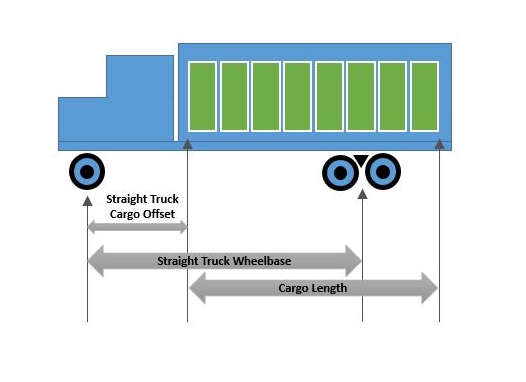

In order to estimate the axle weights, Load Planning needs certain measurements for the equipment being used to carry the load. The following two diagrams highlight those measurements for a tractor-trailer configuration and a straight truck.

Assuming accurate values for these measurements, the actual axle loads should be fairly close to the estimates provide by Load Planning. These estimates also assume that the loading process is executed according to the load plan and that the stated weights for each of the products loaded on the vehicle are accurate. Some variability can be expected due to other factors such as the amount of fuel in the vehicle, differences in configuration (such as tandem placement) between specific vehicles of the same type, and additional items placed in or on the vehicle (e.g., snow on the roof). The estimated axle loads are applicable to static loads (non-moving vehicles) on a level surface.

Tractor-Trailer Measurements

There are five lengths that will need to be measured for the load planning algorithm to work efficiently with a tractor-trailer. These 5 measurements are:

- Tractor Wheelbase – The distance from the center of the front axle to the center of the drive tandem.

- Fifth Wheel Offset – The distance from the center of the fifth wheel (the position occupied by the kingpin) to the center of the drive tandem.

- Trailer Wheelbase – The distance from the kingpin to the center of the trailer rear tandem.

- Kingpin Offset – The distance from the kingpin to the forward-most extent of cargo in the nose, excluding the width of the exterior frame of the trailer and any unused space ahead of cargo in the nose. In certain (somewhat unusual) cases, the kingpin sits at a position that is ahead of the forward extent of the cargo — in these cases, the kingpin offset will be negative.

- Cargo Length – The distance from the nose to the tail, inside the trailer, of the cargo when all positions are filled (using standard full-sized pallets or other containers), excluding any unused space in the nose or tail.

Straight Truck Measurements

There are three lengths that need to be measured if using a straight truck for load planning. These 3 measurements are:

- Straight Truck Cargo Offset – The distance from the center of the front axle to the front of the cargo.

- Straight Truck Wheelbase – The distance from the center of the front axle to the center of the drive tandem.

- Cargo Length – The distance from the nose to the tail, inside the truck, of the cargo when all positions are filled (using standard full-sized pallets or other containers), excluding any unused space in the nose or tail.

Both the tractor-trailer and straight truck measurements can use any reasonable metric such as feet, inches, etc., provided all of the measurements use the same unit of measure.

Tare Weights

Along with the length measurements, three weights will need to be taken as well. The weights are:

- Tractor Tare Weight Front Axle

- Tractor Tare Weight Drive Axle

- Trailer Tare Weight Rear Axle (only applies to tractor-trailer configurations)

Tare weights are the observed scaled weights on each axle when the tractor and trailer are empty. When measuring for the tare weights, the tractor should be fully fueled.